The global supply chain crisis is hitting businesses up and down every business sector, including beers, wines and spirits. Hillebrand’s Emmanuel Olivier helps explain what is causing it.

Global shipping problems are “unprecedented” and “we have never been in a position like this” is the stark warning from Hillebrand, one of the world’s biggest and most influential freight forwarding companies. Emmanuel Olivier, director of ocean freight procurement at Hillebrand, insists it does have the “solutions” to help drinks companies but clearly if this is the first time it has been faced with a shipping crisis as bad as this any “solutions” have to be untested and not guaranteed.

Speaking in a Wine Australia hosted webinar this month he painted a picture of a perfect storm of problems for global logistics and supply chains. They include:

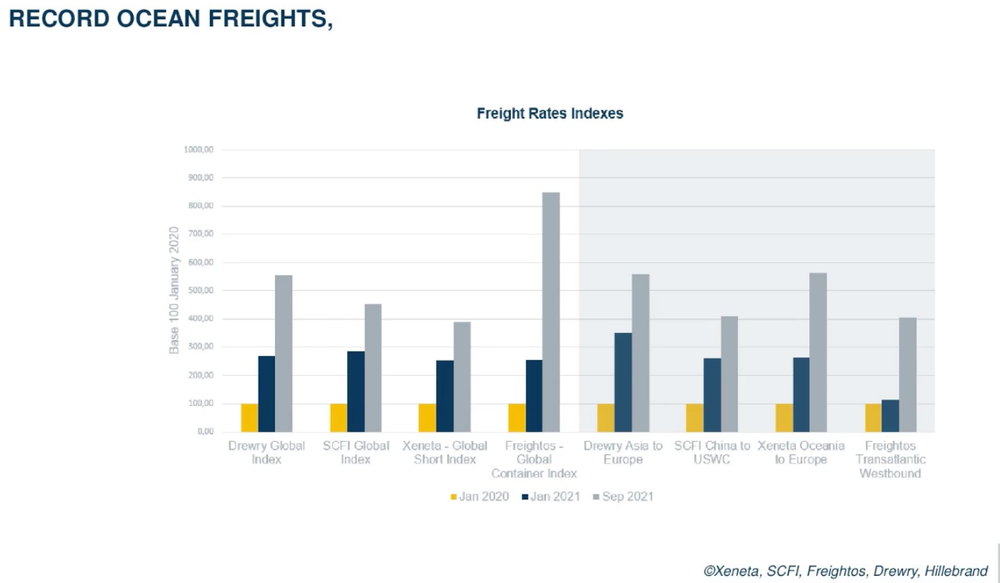

- Ocean freight rates are at all time “record levels” and are increasing on every route in the world.

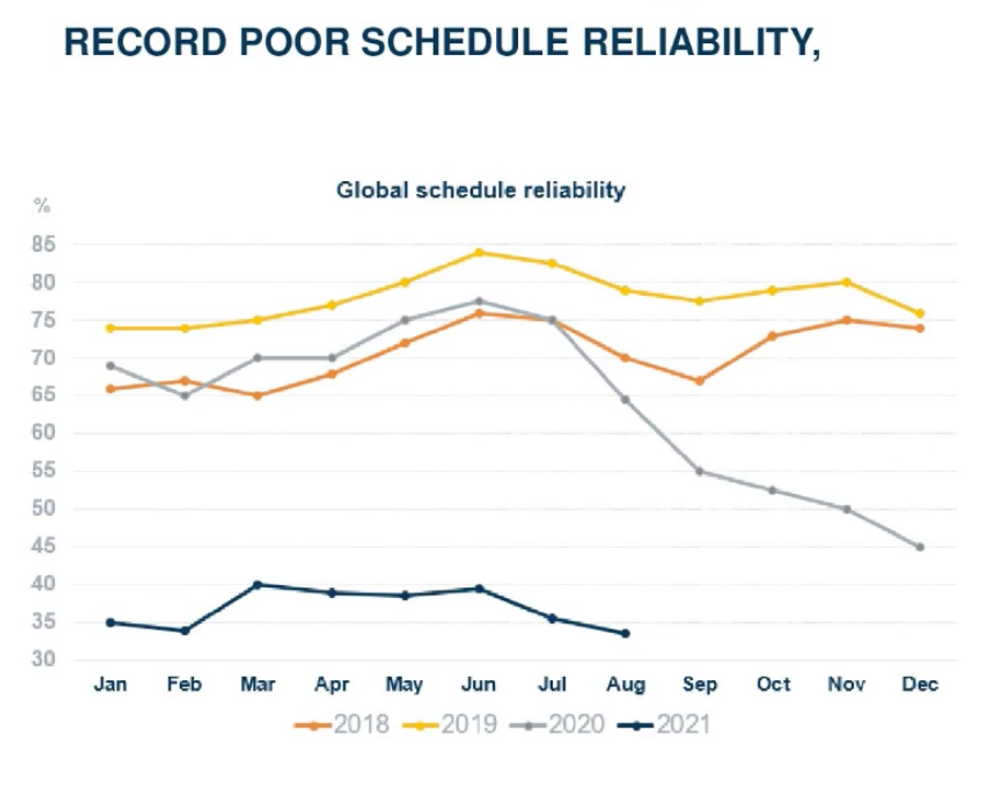

- Schedule reliability is at a record all time low and that you only a 35% chance that your cargo will be delivered on time. The Asia to EU shipping line is as low as 20% of shipments arriving on time.

- A 13-15% growth in demand for containers around the world in 2021 which is still up 6-7% up 2019 which is resulting in a shortage of available containers.

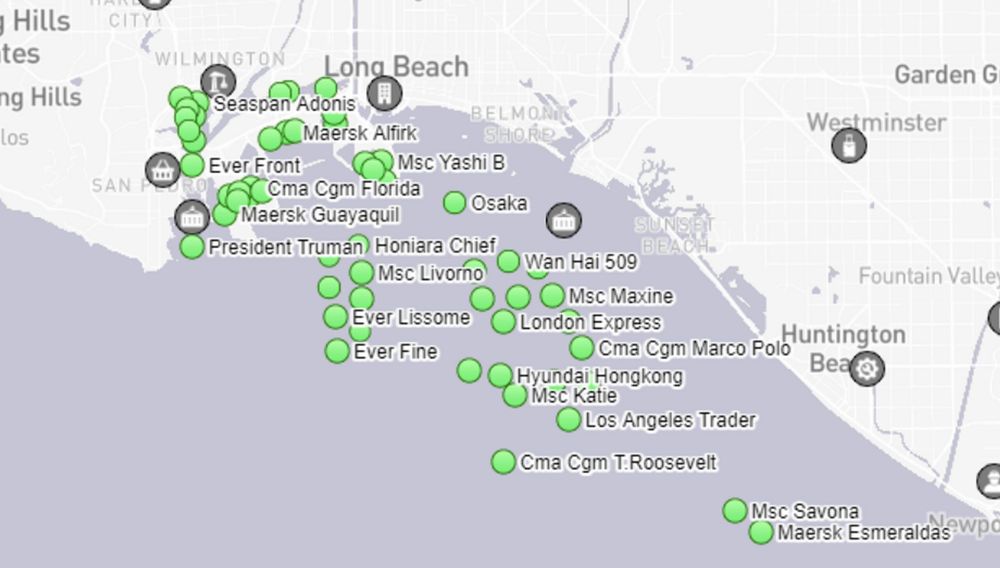

Separately at Goldman Sachs analyst reports claim delays and backlogs at global ports could last until at least the “middle of 2022″ and that there is $24 billion in goods sitting on ships outside California’s Los Angeles and Long Beach ports. “[There is] No immediate solution for the underlying supply-demand imbalances at US ports is available,” said the report based on economists’ research. It also claims it is taking around 80 days to transport goods across the Pacific, twice as long as before Covid-19

It’s not a computer game but an image of ships sitting out side Los Angeles port

All of which is resulting in record profits for the ocean freight carriers, including Hillebrand, up over 50% for some. Maersk, the world’s biggest shipping company, reported in September it is expecting EBITDA of $22-23 billion in 2021 against previous expectations of USD 18-19.5 billion.

“The industry has never recorded that level of profitability for the ocean carriers,” said Olivier, who also stressed this goes some way to balance the years of losses in the sector that has resulted in consolidation and the rise of a few dominant players. Hillebrand itself was taken over by DHL in September in a $1.5 billion deal.

Capacity challenge

Shipping lines, he stressed, have responded to try and get as much capacity as it can into the supply chain, but the industry is also having to re-balance itself having had to shut down so much of its capacity when the pandemic struck in the first quarter of 2021. Transatlantic capacity, for example, is up 63% and Europe to Asia up by 25% and some lines have done better than others depending on where the initial demand came from.

But with such “unprecedented” change it is perhaps not surprising the supply chains infrastructures could not cope, he added. Particularly as the world did not come out of lockdown at the same time. So as Chinese factories and manufacturing plants started working full time again much of Europe and North America was still living with major restrictions on movement and people.

“All of a sudden you have a boost in cargo coming to the ports that had trucking capacity, warehouse capacity and terminal capacity totally inadequate with the sudden demand and volumes coming to the port,” said Olivier.

The situation is so bad that no freight forward shipping company can guarantee when a shipment will arrive, says Hillebrand’s Emmanuel Olivier (Chart source: Sea Intelligence)

All of which means the traditional supply chain is “broken” which all stems from the major ports, starting in North America, not being able to cope with the extra demand, he claimed. The average waiting time for a ship to enter a California port in July was seven days – some have had to wait up to 25 to 30 days to get a berth. There are currently around 70 ships waiting to get into Californian ports.

Such long delays essentially means the capacity increases being laid on by the major shippers and freight forwards is being made “ineffective by the inability of the ports to cope”. Which has resulted in a negative impact on capacity growth which Hillebrand estimates to be €800,000.

When the global supply chain works well it is because it is so well interlinked between goods being sent from warehouses to docks, to ships, to being offloaded and then sent to their final markets. When it falls down it means all those links in the chain are hit. Which is where we are now. Made even worse by the lack of labour at each stage of that supply chain, said Olivier.

The situation has got worse because the knock-on effect of blockages and delays at ports then “cascades” down the supply chain.

It means no shipping or freight forwarding business can “guarantee” an arrival date for any order that has been placed in the last three to four weeks, he added. That “guarantee does not exist” as schedules are being changed all the time.

The enormous rise in freight rate costs

US is key

The situation, he stressed, is not going to get much better to help with the festive season and will certainly carry on well into 2022, particularly as the rate of new ships and containers being built will not outstrip the capacity shortages in the market.

The key factor, he added, is the “productivity and performance” of the US ports. If those do not improve then the global situation is unlikely to get any better. It is too early, he added, to see what impact some US ports opening up 24 hours a day will have.

The cost of freight forwarding is also going up enormously due to higher oil prices, but also the amount that shipping lines are now being asked to charter vessels. What was a fee of around $10,000 to $15,000 a day is now $140,000 a day and even then you might have to factor in a minimum three week waiting period at ports.

It’s perhaps not surprising that Olivier would recommend drinks businesses tie down long term partnership with major freight forwarders like Hillebrand. But, he stresses, as a specialist in the drinks industry it has the contacts and networks to be able to offer “a raft of solutions” – from air freight to groupage – that might help in the months ahead.

- You can watch the full Wine Australia webinar with Hillebrand here.